*** Please note that clicking on any image will give you an expanded view. *****

Another weekend has come and gone and I was able to get out to my forge 2 times this week. The first day (Sunday) i set out with 3 goals:

Work on the new anirons for the upstairs fireplace.

Begin the work on a medieval shovel blade for Mistress Lorelei

Forge weld a piece of round stock back on itself

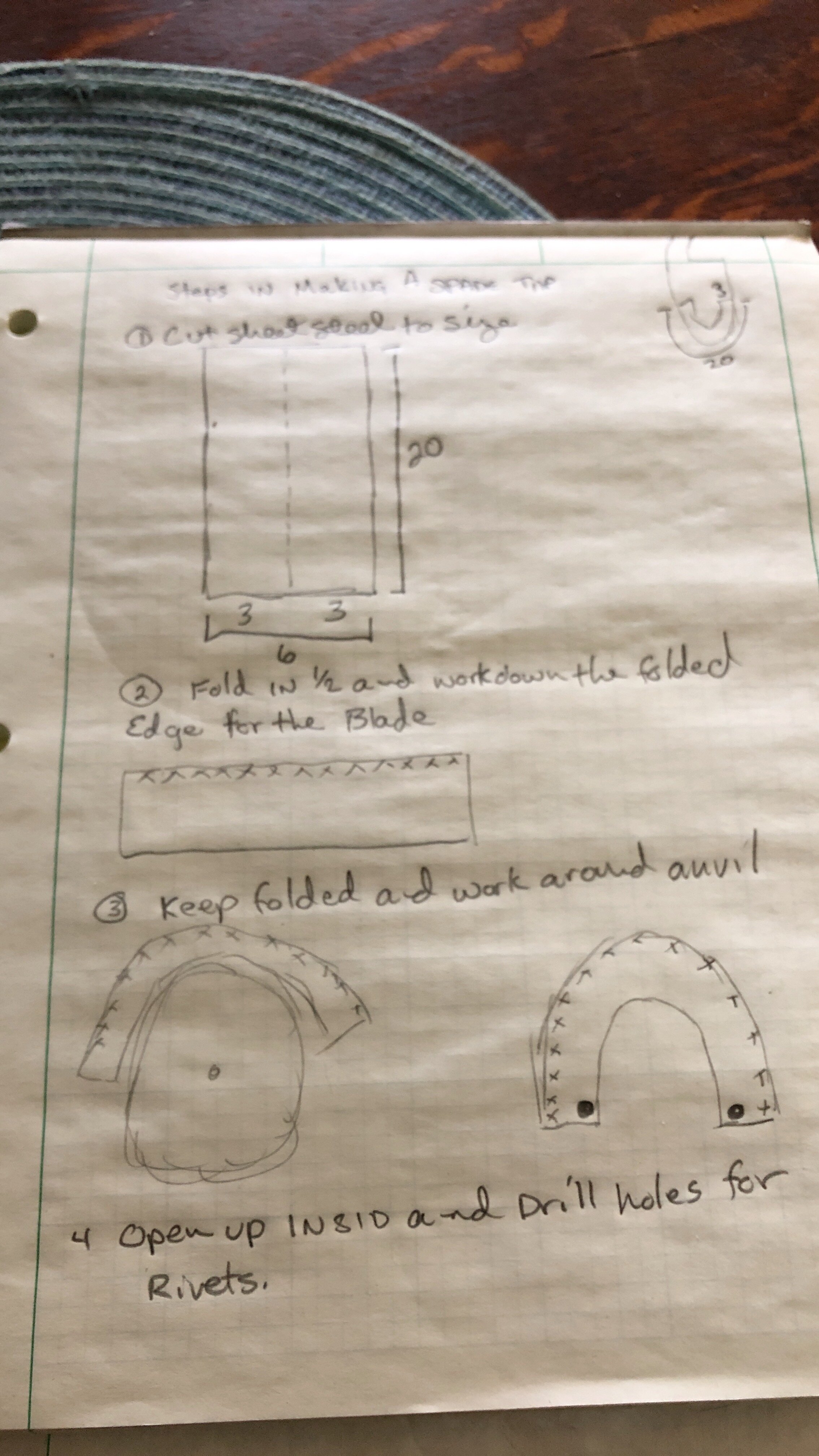

Started on #2 first. My first thought was to take a piece of thin stock, fold it in half and then bend it to shape. This would make the fold the edge and create the space for the wood to be inserted.

The problem with this plan was the lack of movement allowed in this thin of metal. There was just no room for the expansion and contraction needed for the proper shape.

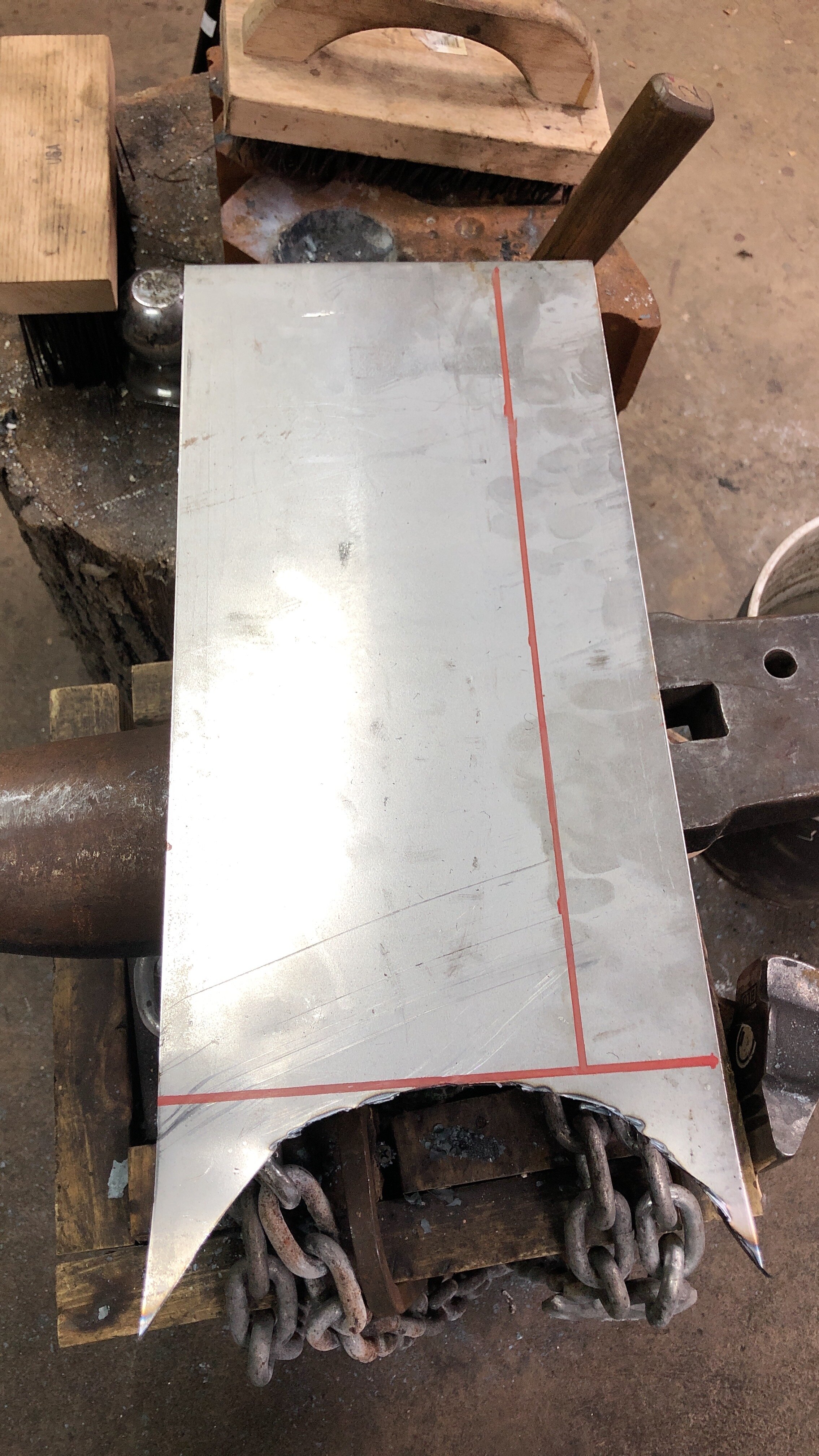

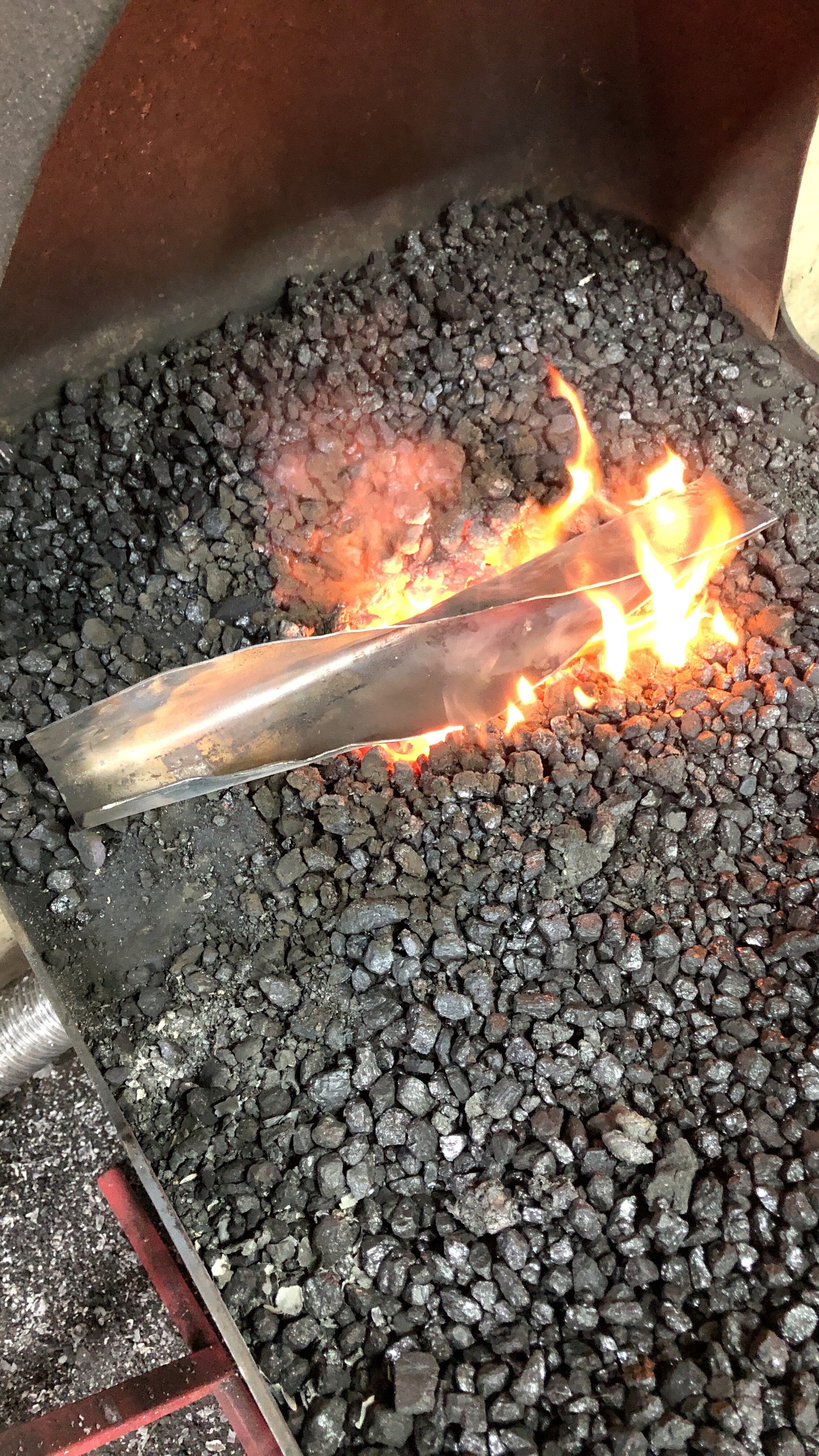

The next plan of attack was to use steel with enough thickness to make the bend and then draw it out to the proper thickness. For this, i started with 18 inches of 1 1/2 by 1/4 inch bar stock. This was then folded over on itself to create a 3/4 by 1/2 piece of stock with a cut down the center.

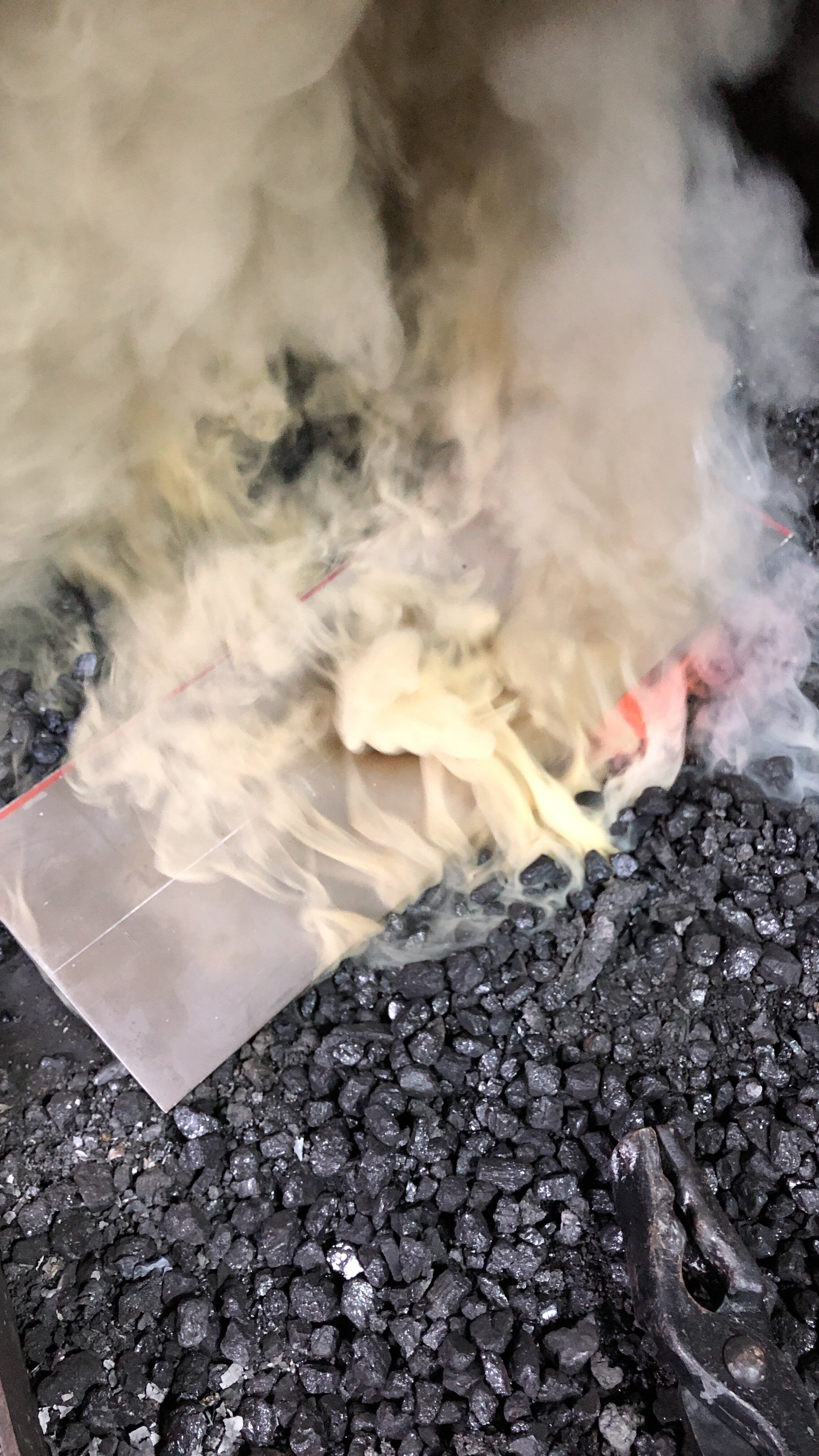

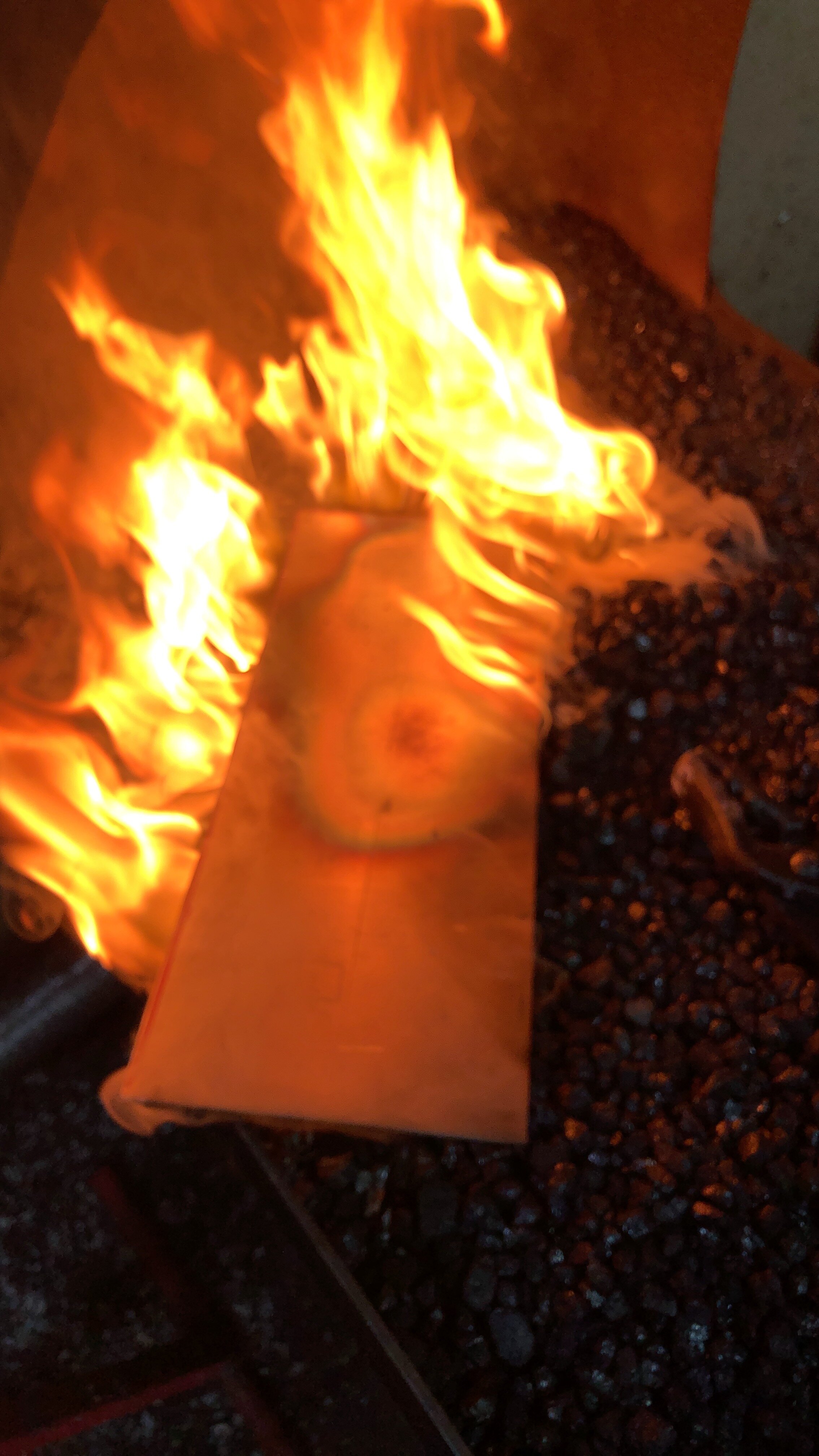

Once the “taco” was created, the bend was then forged into the bar in the shape of a spade head. This was then hammered flat and spread to create 2 thin sheets joined by the fold. As long as I did not heat the metal to forge welding temps, the 2 sheets would remain separate. .

Because of the shear mass of metal that needed to be moved, i was working with my 3 lb hammer instead of my normal 2. The peen end on this moved metal quite well and I was able to make some good progress on it. The trouble is, I am not in shape to swing a 3 pounder for very long, As my hammering time became less and less, i decided to stop on this for the day and switch to my other projects.

With fatigue knocking at the door, I set myself the task of creating 1 pinon for the fireplace anirons:

Working on this also included making a monkey tool holder to allow me to drive the metal into the monkey tool instead of hammering the monkey tool onto the rods.

Mow, with my few remaining hammer blows, it was time to work on making a closed loop on the end of a 1/4 in rod. The books and videos claim this is easy as pie, but i must question the accuracy of this statement. It might have just been my weakened state, or possibly the dirty-ness of a fire that had been going for hours, but this was a dismal failure. By the 3rd try, i was able to get some of the metal welded, but not enough to call it a success.

With this, I was DONE! There will be other days to forge…..

In fact, today (Tuesday) was one of those days. I was able to slip out of work a few hours early, and the wife was off riding. So, Hammer Time! Today was just working on the spade for Lorelei. I was not able to meet my 2 inch draw out goal, but came close to 1 1/2.

The final step for today was opening up the 2 edges of the shovel. This was done cold with chisels. I hope there is enough material for a shovel to be firmly attached. We will just have to wait and see. if you would like to subscribe to this, please click on the link at the bottom of this page.